ECAD/MCAD integration is a necessity in today’s world. See how Fusion 360 can make electronics to mechanical workflows easy.

The product development process has changed. Gone are the days of designing in our separate boxes, passing PCBs and enclosures down the line. These days, if you’re developing in ECAD, you’ll likely need MCAD as well — whether it’s to throw together an enclosure, verify fit, or run a simulation. We’re not just PCB designers anymore; we’re product developers.

When was the last time you designed just a PCB?

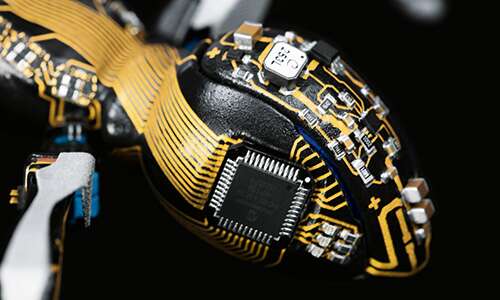

It’s rare to find an electronics designer making only PCB designs these days. Electronics are the unseen intelligence in our world, and they always need a physical counterpart to connect with humans. It’s human nature to love touching buttons, switches, and boxes.

However, there’s still this myth that we can exist as engineers in only our ECAD software in an age of smart, connected devices. How does this hold up, though? There are currently over 46 billion connected devices around the world. There will continue to be devices that require smaller package sizes and integration between the electrical and mechanical domains, unlike anything we’ve ever seen before. How are you going to design all of that with one tool?

This is just the start of our problems, though. Since the beginning of the Industrial Engineering Era, we have been relying on file formats as our sole method of collaborating and sharing design data. You know them by name – STEP, IDF, BRD. The dance is always the same: pack your data up, email it back and forth, and hope for the best.

Why ECAD/MCAD?

As product development changes, electronics design needs to follow. We need to start seeing our PCB designs from a broader perspective, in a 3D world, as part of a complete product development workflow. There are three main reasons why every electronics designer needs to have comprehensive ECAD/MCAD tools in their toolbox to prepare for the coming change:

- Collaboration is now a necessity. Today’s design process is anything but linear. Component availability changes and board layouts need to shift to fit enclosures last minute. Not having a way to understand how your product affect your PCB design process is handicapping your capabilities.

- File formats are a burden. Putting your design in a box as a file format naturally lends itself to errors in translation. When was the last time your STEP file fully communicated your design intent? Probably never. I think it’s safe to say we’re all tired of pouring hours into documentation just to supplement what your design should already communicate.

- The future is blending disciplines. Engineers are expected to do it all; documentation, emails, design, sourcing — you name it. Mechanical design is now on this list as our need for smart devices deepens. And have you seen molded interconnect devices (MIDs)? You won’t be designing those boards only in 2D.

You need answers

Product development might have changed, but some tools aren’t keeping up. As electronic designers, we’re still looking at an industry of disconnected toolsets. Are you working in Altium Designer? Prepare to spend thousands on SolidWorks. That’s just one classic example where neither of these tools communicate outside of file exchanges.

This is why we created Autodesk Fusion 360.

Autodesk Fusion 360 can answer so many of the problems electronic designers face now and in the future. You might know it by name, but what exactly is Fusion 360? It’s cloud 3D CAD, CAM, CAE, and PCB, all in one tool. We see design teams all over the world using Fusion 360 to:

- ECAD/MCAD Co-Design. The cloud-based design environment allows all engineers to quickly iterate ideas and bring function and form together on any device.

- Simulate. Engineers can test fit and motion, perform simulations, and generate realistic renderings all in the same tool.

- CAM. When it’s time for manufacturing, it’s easy to create toolpaths for machining or use the 3D printing setup to bring a prototype to life.

In the past, electronic designers were typically left out of the product development process in 3D CAD. The question was always the same: how do you bring the 2D world of electronics into a 3D world? Fusion 360 not only solves this integration problem but it completely removes it by making the ECAD tool the MCAD tool. Finally, there is one unified platform in a single dataset. Finally, electronics engineers can design in a new dimension (pun intended).

Design Unification

Fusion 360 enables ECAD and MCAD designers to work natively and independently on the same design project and within the same design management platform. This allows engineers and teams to share:

- One common design environment

- One common design management system

- One design dataset with no file exchange, export, or third party integration ever needed

Ultimate ECAD/MCAD Collaboration

Autodesk Fusion 360 offers a truly connected experience for PCB, Mechanical, and overall product design, ensuring every stakeholder is part of the product development cycle. With one cloud-based data management — powered by our AWS partners — collaboration between all stockholders becomes an integral part of the design process in Fusion 360. This ensures change is seamlessly managed, be it revisions, board shape updates, component moves, library updates, or enclosure changes. This means:

- Real-time ECAD-MCAD collaboration

- Design changes can be fluidly passed and initiated by either ECAD or MCAD

- Stateless and Concurrent design process

True 3D PCB design

With both ECAD and MCAD working on the same Fusion 360 environment with one dataset, 3D PCB data such as board copper, core material, and components can be analyzed, verified, and validated on the MCAD side to ensure they meet product design specifications, including:

- Specify 3D PCB data properties such as copper to run design simulation

- Check for collisions and interferences

- One source of truth ensuring design teams working on the most recent dataset

Yes, product development has changed, and so has the tools you need for your daily work. Whether you’re working as part of a design team or flying solo, the days of just needing multiple tools to get the job done are gone. But this presents a whole new set of problems. Do you fork out thousands of dollars for a traditional ECAD/MCAD bundle, getting two different tools that barely communicate together?

We can do better. Try Fusion 360 electronics today: