CAD/CAM software is computer-aided design & computer-aided manufacturing software for CNC machinists.

Start machining today with integrated CAD/CAM

60%

Reduce your time to market by 60% with one CAD/CAM solution.

1/2x

Cut costs in half by reducing cycle times and unnecessary hours spent.

50%

Create toolpaths twice as quickly and start machining faster.

Get to machining faster

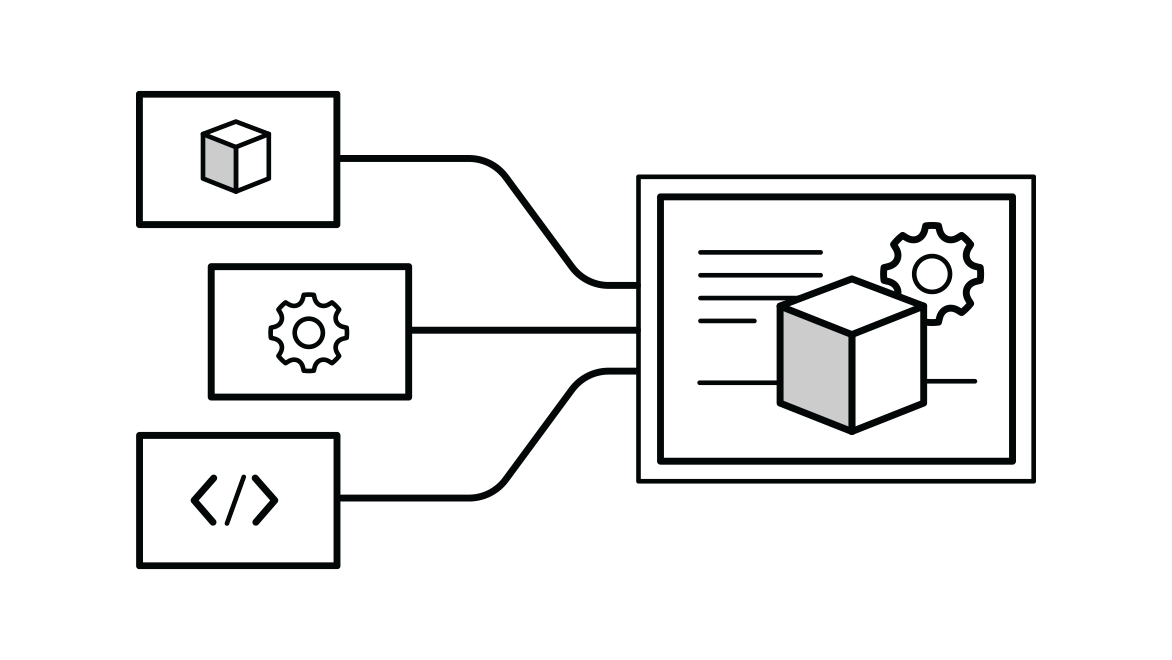

Quickly import designs with the largest set of CAD data translators for 50+ different file types. Edit existing features or model fixtures with a truly integrated CAD/CAM platform.

Generate toolpaths in minutes

Quickly create multiple design iterations. Fusion 360’s flexible software enables you to design effortlessly.

CAD/CAM at a fraction of the cost

Stretch your budget further by eliminating costly, disparate CAD/CAM tools with one integrated solution.

Features

Design to manufacture

Fusion 360 makes it easy to program CNC machines. Use simplified controls for high-efficiency roughing, adaptive clearing, and tool orientation. Design for 2D up to 5-axis milling. Simplify probing, turning, mill-turning, and profiling operations with a powerful post engine.

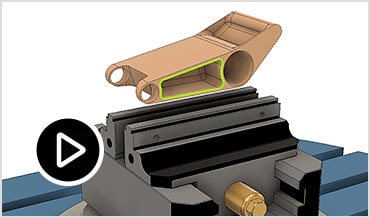

2D and 2.5D machining

Set up jobs and create 2D and 2.5D toolpaths to drive CNC routers, mills, water jet cutters, laser cutters, and more. Integrated CAD simplifies design revisions, reduces programming times, and helps avoid mistakes.

3-axis machining

Create high-quality NC code using powerful 3-axis machining strategies. Rough and finish your 3D parts with intuitive workflows. Add the Fusion 360 Machining Extension and program individual features or entire parts.

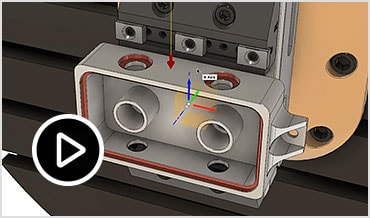

Multi-axis positional machining

3+1 and 3+2 (positional) machining lets you machine parts with fewer setups. Use shorter, more rigid cutting tools to improve part accuracy and faster cycle times. Add more multi-axis capabilities with a subscription to the Fusion 360 Machining Extension.

4 and 5-axis simultaneous milling

Use specialized 4 and 5-axis toolpaths to achieve superior surface finish. Get more tool axis controls with the Fusion 360 Machining Extension. Automatic collision avoidance will help you achieve safe, smooth, and predictable machine motion.

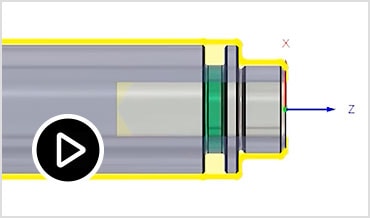

Turning

Program 2D turned parts using a suite of dedicated turning strategies. Verify your turning toolpaths with stock simulation. Identify errors or collisions with the model, stock, tools, and workholding.

Turn-mill

Produce more complex parts by combining milling and turning operations. Generate NC code for multi-tasking hardware, capable of supporting both styles of machining.

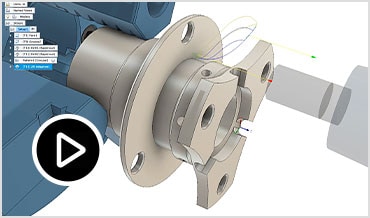

Setup probing and part inspection

Use spindle-mounted touch probes to monitor and control your CNC machining. Save more time by automating part setup with the Fusion 360 Machining Extension. Measure stock material, update work offsets, track quality, and more.

Fusion 360 Machining Extension

Get access to the Machining Extension to unlock added capabilities in Fusion 360. Automate 3+2 machining, 4- and 5-axis simultaneous machining operations. Simplify toolpath modifications, surface inspection, part alignment, and more.

Advanced machining with Fusion 360

Need more advanced CAD/CAM technologies? Reduce CNC program time with 5-axis programming, toolpath optimization, process automation, on-machine verification, and more. Improve the quality and value of your finished parts.

Winning with Fusion 360

A leader in aftermarket motorcycle parts uses Fusion 360 to design and manufacture precision CNC parts. CAD/CAM integration helps them exponentially grow their business.

"Our very first project using Fusion 360, we saved over $14,000 by reducing cycle time by 9 minutes."

– Daniel Colbert, Colbert Manufacturing

Frequently asked questions for machinists (FAQs)

Computer-aided design & computer-aided manufacturing (CAD/CAM) software is used by CNC machinists to design and manufacture prototypes, finished products, and production runs of products.

CNC stands for computer numerical control. There are many types of CNC machines, and this is often the main step in the process of creating a component or part through material removal. Once a part has been designed in CAD software, CAM (computer aided manufacturing) software is used to generate toolpaths, plans that tell a CNC machine how to move.