Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

Generative Design Customer Stories

-

Hyundai is driving mobility innovation with generative design technology

Hyundai Motor Group’s New Horizons Studio is pushing the boundaries of vehicle design with walking car concept.

-

Creating one of the lightest wheels in the world with generative design

Using Generative Design with 3 and 5-axis milling, Briggs Automotive Company created new wheels that are 35% lighter.

-

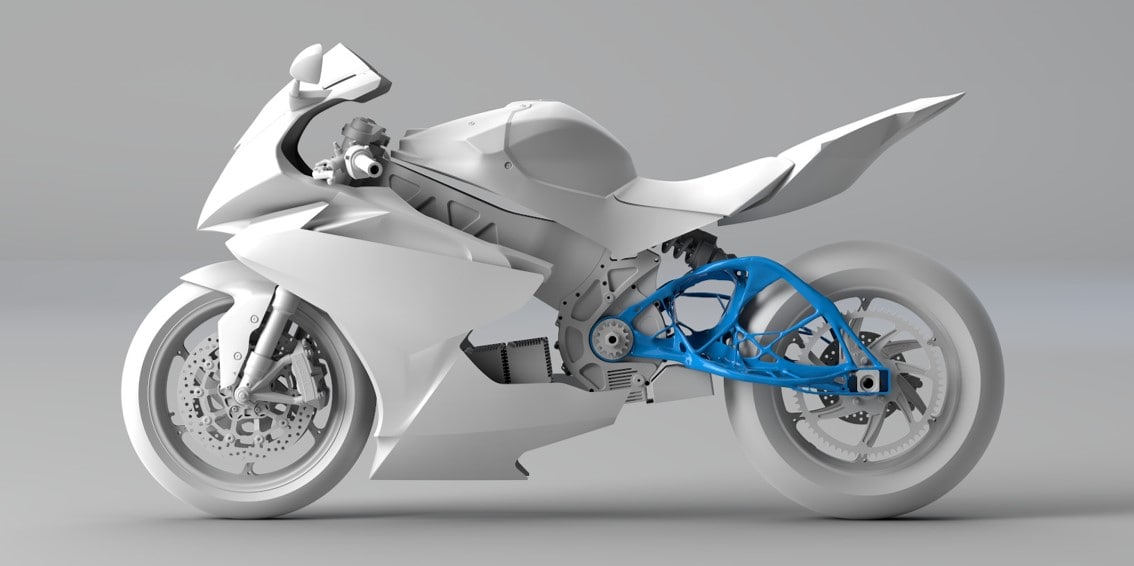

Exploring machinable options for motorcycle parts with generative design

MJK Performance, a Canadian motorcycle parts manufacturer, uses generative design to optimize triple clamps for 2.5 axis milling.

-

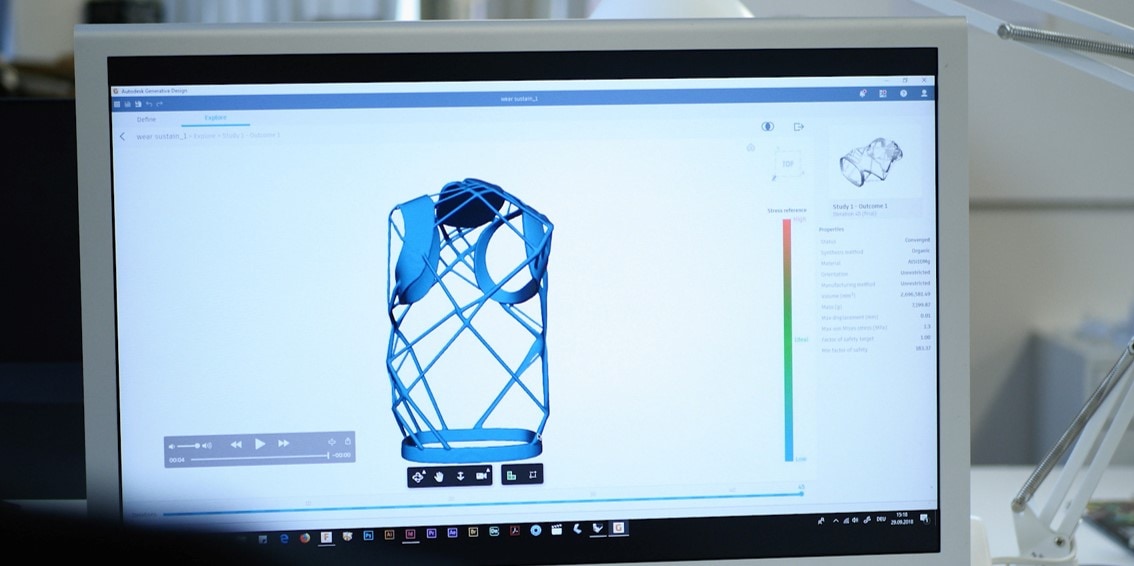

Revolutionizing back protection using generative design

Using generative design technology, Edera Safety has created a revolutionary new back protection system for athletes.

-

Volkswagen uses generative design to redesign epic bus

Autodesk collaborates with Volkswagen Group on generative design in electric showcase vehicle.

-

How generative design is reinventing heavy equipment

The engineers at Claudius Peters used generative design to reinvent its clinker cooler, reducing materials by 25%.

-

Automotive lightweighting with generative design

General Motors achieves 40% weight reduction on new seat belt bracket with generative design and additive manufacturing.

-

Generative design helps to break speed records

Generative design and additive manufacturing helped Lightning Motorcycles to design lighter and faster motorcycles.

-

Creating a better interplanetary lander with generative design

NASA's JPL used generative design technology to design a new concept lander with 35% less mass and improved performance.

-

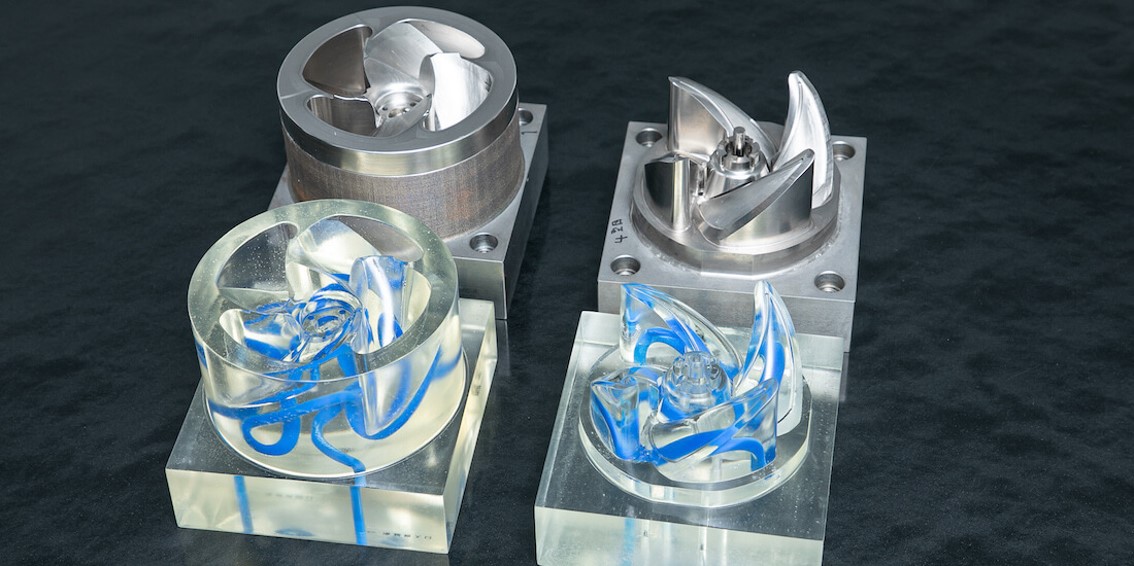

Saving Panasonic engineers' sanity with generative desing and injection-mold cooling

Generative design could help engineers to save time developing advanced cooling systems for melted materials

-

How Honda used generative design to create a lighter crankshaft

Using generative design technology, Honda's engineers were able to reduce the weight of a crankshaft by about 50%.

-

AI driven chair design by Philippe Starck and generative design

The A.I. chair is the fruit of collaboration between a.i. driven generative design and Philippe Starck.

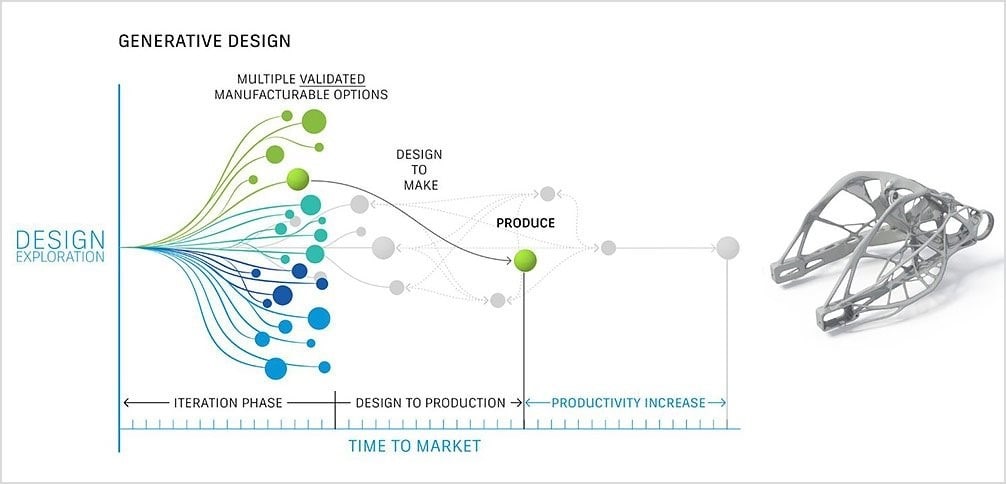

What is generative design?

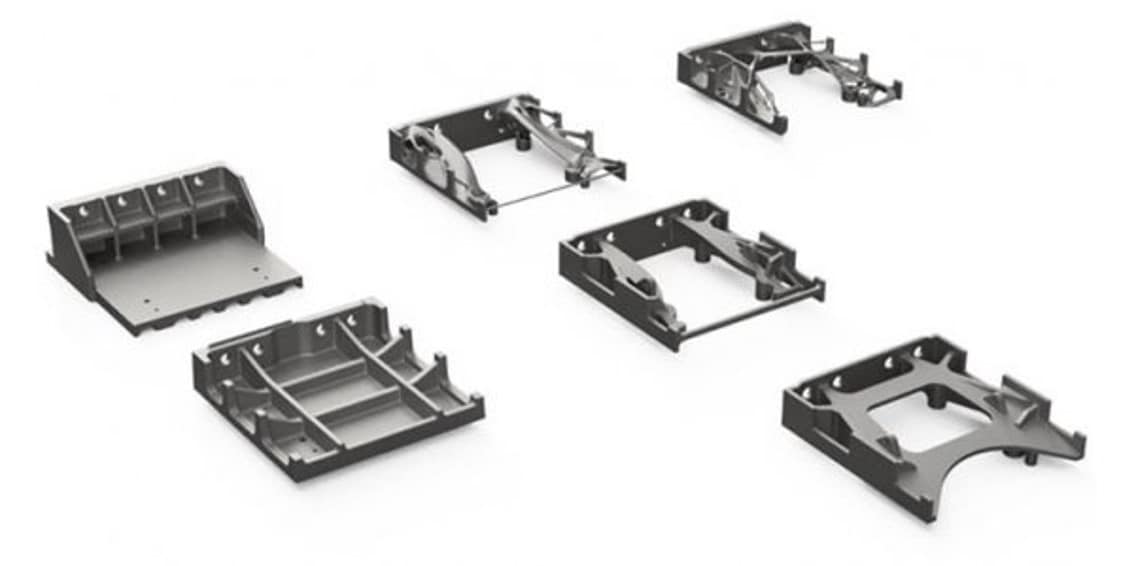

Generative design technology expands your ability to deliver innovative design and engineering solutions. Based on parameters such as performance or spatial requirements, materials, manufacturing methods, and cost constraints generative design software simultaneously creates multiple CAD-ready alternatives.

Generative Design Articles

-

Does generative design work in the real world?

By targeting the right problems, companies can apply generative design in a number of different ways to yield value-added benefits.

-

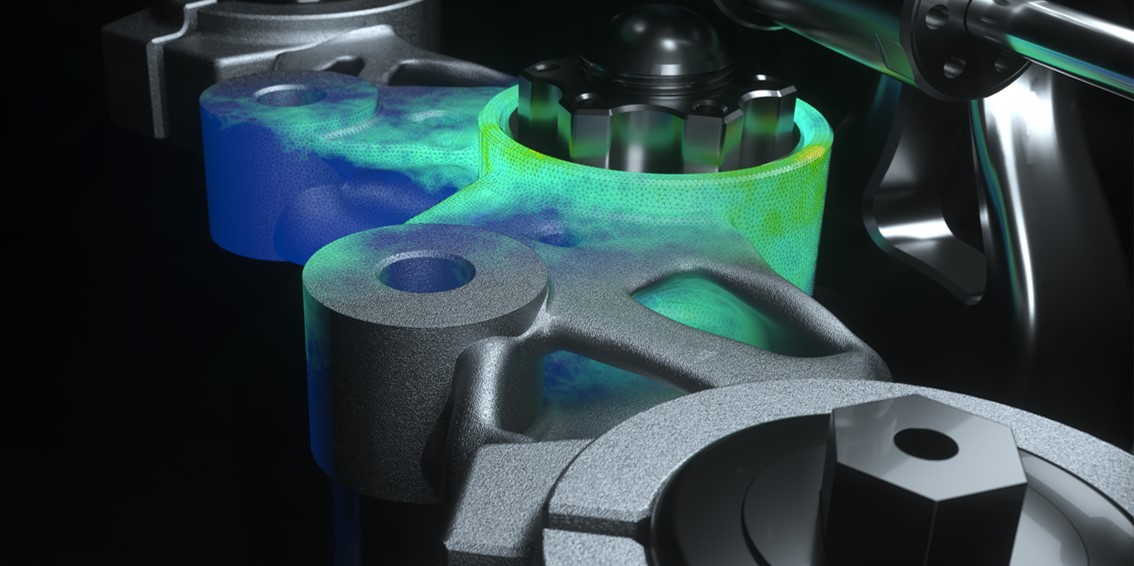

Does generative design work with metal casting?

Generative design optimizes traditional casting methods, helps to uncover novel design possibilities, and boosts productivity across the factory floor.

-

Can generative design propel sustainability in the manufacturing industry?

Generative design holds the potential to accelerate sustainability gains in the manufacturing industry in the future.

-

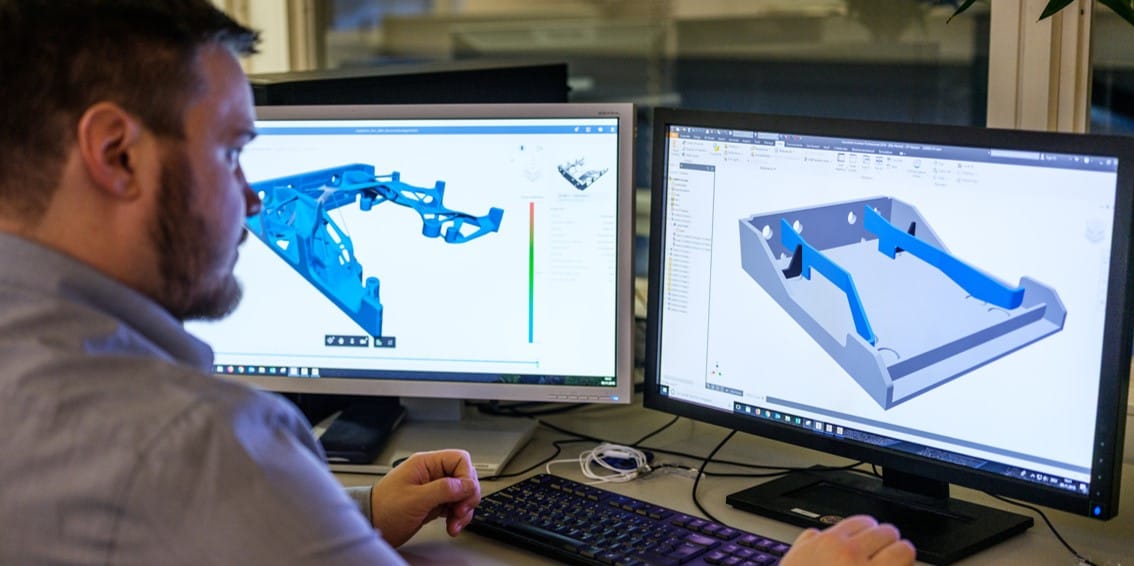

Optimize traditional manufacturing methods with generative design

Examine how generative design can be used to help engineers identify and optimize traditional manufacturing methods like CNC machining

-

Solve budget constraints and design challenges with generative design

Explore how cost-conscious generative design can now help engineers keep within budgetary constraints while producing innovative designs.

-

Three ways generative design is transforming business

Autodesk generative design is making the convergence of design and manufacturing a reality by implementing concurrent engineering as a technology-enhanced, automated process.

-

In case you missed ’em:

6 examples of generative design in manufacturingManufacturers of all sizes have been using generative design increasingly for everything from heavy machinery to safety harnesses.

-

The promise of manufacturing automation for all starts with generative design

As a manufacturer, you’re certainly familiar with the concept of generative design by now—but there’s still some confusion over its real definition.

-

Think generative design is overhyped? These examples could change your mind

Autodesk Senior VP Scott Reese sees generative design as the most exciting development the manufacturing industry has seen in the past 20-plus years.

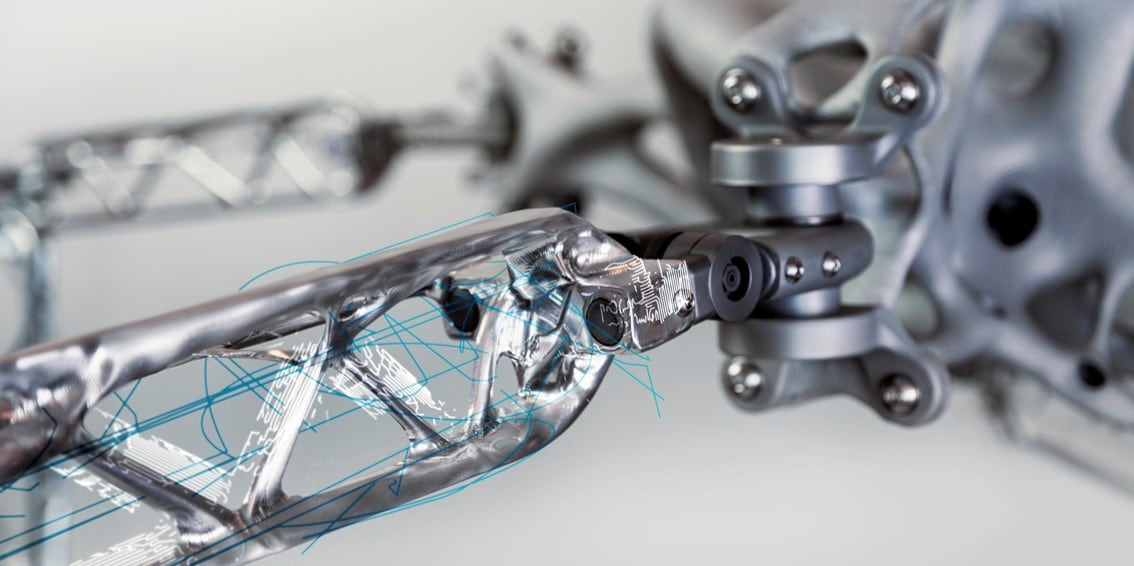

AI-Based Generative Design

Is the Ultimate Collaborator

Whether you’re designing automotive parts to create lighter cars or creating office-space layouts that help foster employee interaction, Autodesk's generative design technology is the ideal cocreation partner.

Generative Design Ebooks & Whitepapers

-

Applying generative design: Improve performance, productivity, and cost

Why generative design is a good fit for today’s most pressing engineering challenges.

-

Generative Design: Redefining what’s possible in the future of manufacturing

Generative design, an ai driven design-exploration process lets humans and machines create together.

-

Harvard Business Review:

The next wave of intelligent design automationGenerative design opens the door to design options that might never have been imagined by engineers on their own.

Generative design

on-demand webinar

Generative design leverages artificial intelligence and cloud computing to enable engineers and designers to simultaneously generate and explore multiple CAD-ready solutions. Based on real-world manufacturing constraints and product performance requirements generative design technology explores all possible permutations of a design solution.