PROJECTS

The Autodesk Technology Centers invite industry, academic, and entrepreneurial communities to pursue cutting-edge projects that shape the future of making.

The Autodesk Technology Centers invite industry, academic, and entrepreneurial communities to pursue cutting-edge projects that shape the future of making.

Working closely with the Autodesk Technology Centers workshop team helped Tulip develop a wireless edge device to monitor analog devices to detect anomalies and identify potential issues.

Working in conjunction with Autodesk Research, the DAISY team is modernizing the construction industry by using artificial intelligence to quickly and efficiently produce structural timber designs.

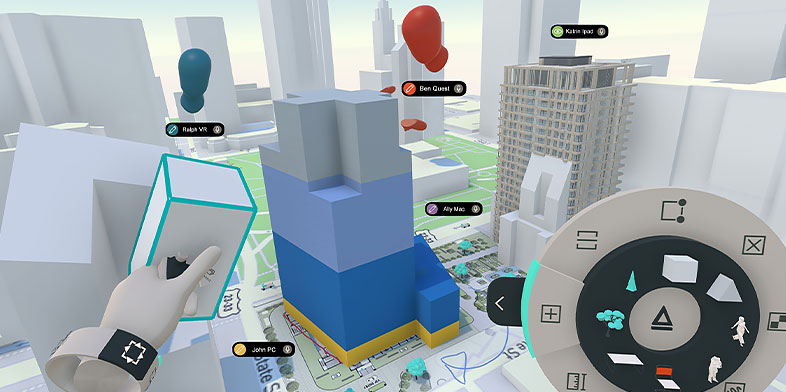

Expert guidance and feedback from the Autodesk Technology Centers Outsight Network helped Arkio add Revit and BIM 360 integrations to its real-time, collaborative, virtual reality architecture design software.

Courtesy of Arkio

Cortex Design brings its human-centered and holistic product development approach to a collaborative effort that makes rapid at-home COVID-19 testing as accurate as lab testing.

Coral Maker collaborated across continents to develop coral skeletons and a robotic seeding technique to make large-scale coral reef restoration possible.

Institute for Computational Design and Construction teams developed novel frameworks for AEC processes using robotic fabrication, computational design, and innovative materials.

Apis Cor develops 3D printers and 3D-printing mixtures that transform affordable housing construction, while Thornton Tomasetti promotes creation of codes and standards for 3D-printed buildings.

PHION Technologies is developing an over-the-air wireless power and data platform that delivers safe, intelligently scalable power to large spaces, simplifying job site logistics and reducing cabling costs.

Courtesy of PHION Technologies

Cosm Medical broke through R&D challenges in designing customized pessaries for women’s pelvic floor disorders using ultrasound scanning, AI image analysis, and 3D printing.

Courtesy of Cosm Medical

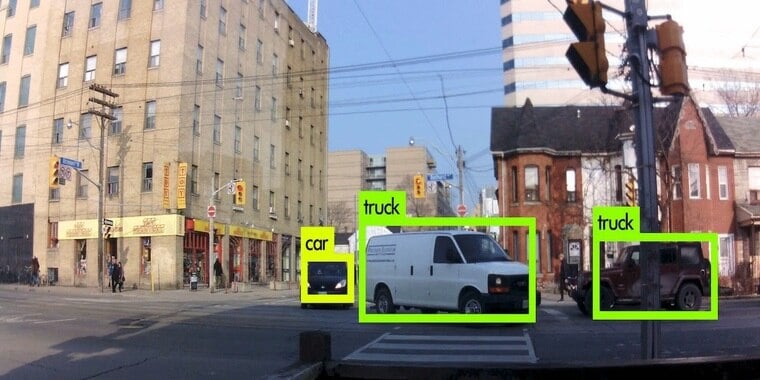

ZEITDice combines low power consumption cameras and edge computing with a cloud-based computer vision platform to provide site monitoring and pattern recognition data.

Marion Surgical is changing the field of surgical education by building the world’s first virtual reality and haptic feedback training platform for surgeons.

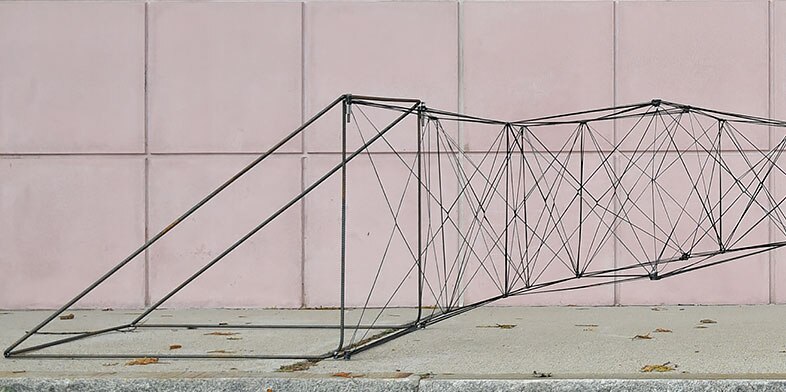

Perkins + Will’s Technology Lab leveraged its previous research into mass timber and robotic fabrication, combining expertise across offices in a year-long effort.

CW Keller & Associates research engineers have been able to advance field and shop strategies through supported access to advanced hardware and software solutions.

By engaging the Technology Center as an equipment partner, Howick has provided a digital-design-to-automated construction platform that has expanded the boundaries of what is possible for both onsite and offsite industrialized construction.

AI SpaceFactory joined the Residency Program at the Autodesk Technology Center in Boston to explore the future of design and construction outside of earthly confines.

LuxMea Studio is one of the Technology Center Residency Program’s prime examples of a successful cross-center residents exchange.

The Okoa Project has developed a motorcycle ambulance trailer to increase access to healthcare in Tanzania.

Working out of the Autodesk Technology Center at the Boston BUILD Space, Braden Leonard and his team are using state of the art equipment to design and build custom prosthetics.

Breeze Automation is creating a new generation of human-safe, dexterous robots and automation for use in unstructured environments or hazardous conditions.

Tri-D Dynamics is bringing metal additive manufacturing to the mass production scale.

Creating intelligent, self-regulating living systems for built environments by combining the very best of technology and nature.

Faced with the reality that his nephew may spend the rest of his life wheelchair bound, Trexo co-founder Manmeet Maggu was determined to build a device to help his nephew walk.

US Sailing has engineered a number of measurement and testing jigs that facilitate the set-up of boats to required standards.