How to buy

Privacy | Do not sell or share my personal information | Cookie preferences | Report noncompliance | Terms of use | © 2023 Autodesk Inc. All rights reserved

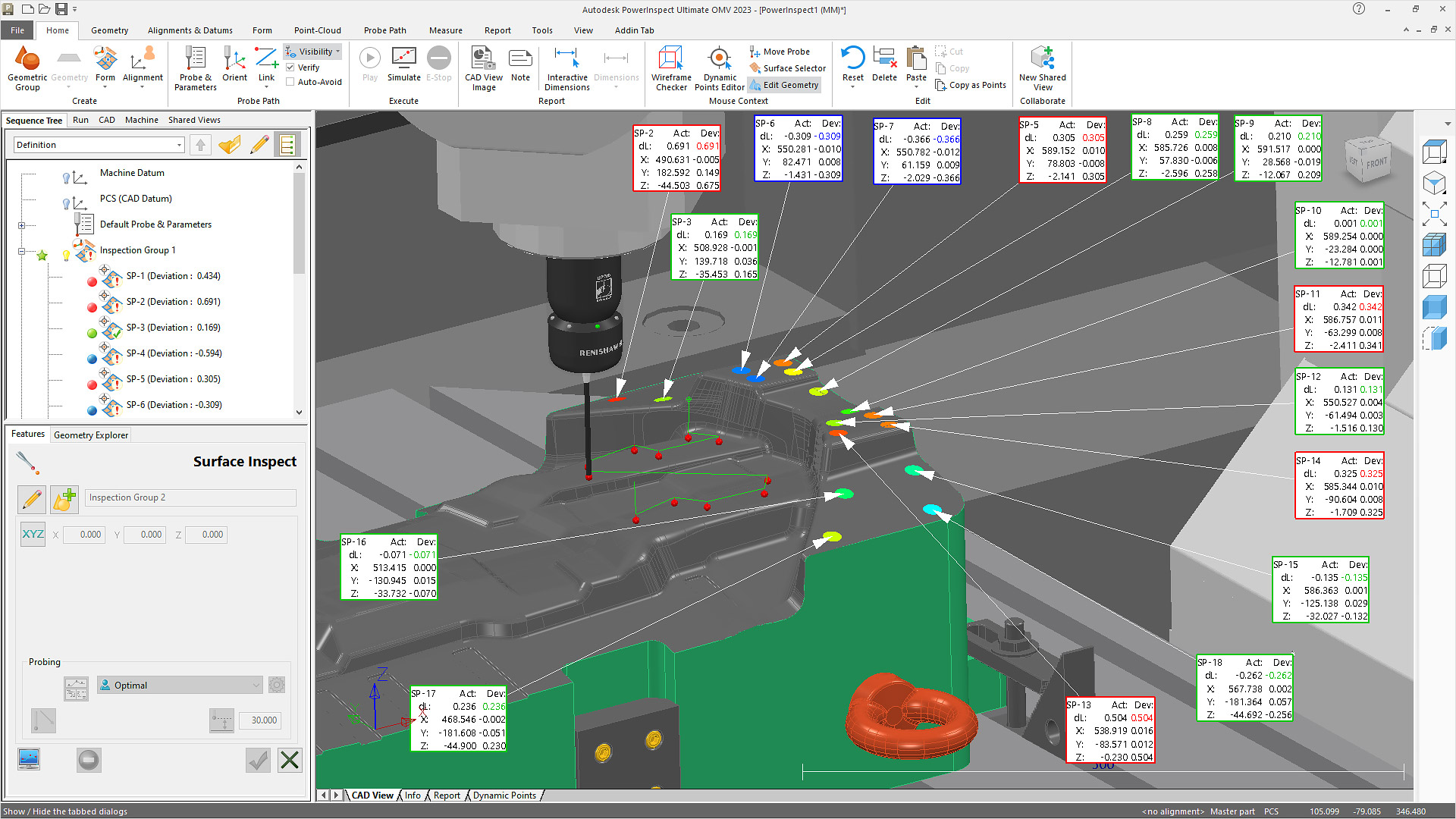

Measure complex 3D shapes with greater quality control. Fusion 360 with PowerInspect supports CNC coordinate measuring machines (CMMs), portable inspection devices, and other inspection hardware.

Use measuring equipment, including CNC CMMs, from a range of hardware providers

Use automated inspection devices such as CNC/DCC CMMs and machine tool probing

Use one interface for all your portable inspection devices, including manual CMMs, inspection arms, and more

Apply the best strategies to inspect complex shapes. Automatically compile results into reports

Explore easy programming for measurement sequences. Measure parts with minimal preparation

Minimize chances of collisions during automated inspections. Simulate measurement sequences offline

Optimize manufacturing with adaptive fixturing, on machine verification (OMV), electrode inspection, and clay milling

Save time and avoid confusion when trying to locate an inspection point within a large session

Automatically fit 2D features from point cloud data and have confidence in measurement results

Embedded strategies

Use scanning and touch trigger strategies to achieve flexible and efficient probing.

Point cloud programming

Inspect fragile or flexible components against CAD data. Extract features automatically from point clouds.

Inspection without CAD

Measure features without CAD. Export results as a CAD file, including IGES and other formats.

Mirror wizard

Quickly mirror an entire inspection sequence and extend the ability to mirror CAD models.

Shared views

Share your engineering data with key stakeholders. Access data anytime using Internet-enabled devices.

Data exchange

(Subscription only)

Get real-time access to the most up-to-date native CAD file translators on the Autodesk cloud.

On-machine verification

Inspect parts while they're still on the machine. Minimize moving parts between machine and CMM.

Electrode inspection

Integrate inspection with design and manufacturing. Shorten setup time and costs for electrode production.

Automotive design

Move swiftly from Alias automotive design software to clay milling on CMMs.

Guided measurement

Use audio and visual aids to help guide inspections, ensuring repeatability and consistency.

Inspection points from CAD models

Import inspection points from CAD data to create inspection points on the part.

Racks and probe databases

Automate inspection sequences with a probe change, with support for the MCR20 and FCR25 CNC racks.